Which Printhead Should I Use?

What we want to try and address in this post is the common question of “which printhead should I use?”. Why is this question so common? Most likely, it is a combination of a large number of options to choose from and a lack of resources to help explain the differences between them. While we can’t do anything about the number of choices, we will explain some of the key factors to think about to help narrow them down. We’ll focus on design, not on supplier. That means we’ll talk about universal considerations such as speed, resolution, frequency, and ink type.

TARGET FEATURE SIZE

The first thing you should think about is what you want the print to look like. Just like the inks you’re hopefully also thinking about, this is set first and foremost by the application. If you are printing a sell by date on a carton of milk, this has a different desired appearance than if you are printing a billboard, or if you are printing a layer of topography on a piece of composite to make it look like wood. Although there are many aspects to the appearance of a print, the factor that is important for deciding what printhead you want to use is the resolution.

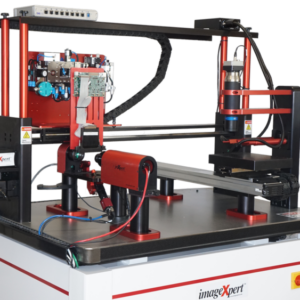

Resolution is expressed in DPI, or dot positions per inch. The higher the resolution, the more printed drops there are per inch, and also the smaller the drops are. Determining the resolution that your application demands is based on many things. Take viewing distance for example. Past a certain distance, the viewer cannot distinguish the difference between a 72dpi image and a 1200dpi image, so printing in higher resolution requires unnecessary time, money, and complexity. The substrate also plays a role in determining what resolution is necessary. The difference between 100 dpi and 1000 dpi is much more apparent on photo paper than a carpet.

Once you have determined the desired resolution, based on testing, industry comparisons, or other means, this means that you can calculate the size of a dot. If there are 360 dots per inch, that means each dot is 1/360 inches in diameter (70.56 microns). Once you know the size of the dot you need, the next step is to determine the volume of a drop that will produce a dot of that size. Most print head manufacturers scale the drop size to the intended resolution making assumptions on the likely amount of ink spread to enable the substrate to be covered. The assumptions on the drop volumes required at each resolution are highly dependent on how much spread there is, which is a property of the ink relative to the surface. This is easier to explain if we consider 1 pass only, as in the table which shows some key attribute of heads printing at two popular resolutions used in label printing 10 years ago and now.

From here, you have estimated the drop volume that is needed to get the print that you want. Luckily, printhead manufacturers specify the typical drop volumes that a printhead will produce, so this should help narrow down the choices from the start.

PRINT SPEED

The next step is to determine how fast the various printheads you are considering can produce images of that resolution and decide if that is acceptable for your application. The way to do this is by comparing the frequency, or number of drops per second, that a printhead can produce – another specification provided by the manufacturer. For inkjet printheads, this is typically on the order of kHz, or thousands of drops per second. By multiplying the number of drops you need per inch (resolution) by the number of drops the head can fire per second (the frequency), you can calculate the maximum speed that you can move the substrate under the printhead. We’ve calculated some drop frequencies as a function of speed in the above figure. Looking at those values, you can see that printing at 1200DPI means you need to eject drops 2-3 times faster. This limits the printheads that you can use to ones that meet the higher resolution and frequency specs, else you have to decrease the speed that you are moving the substrate at.

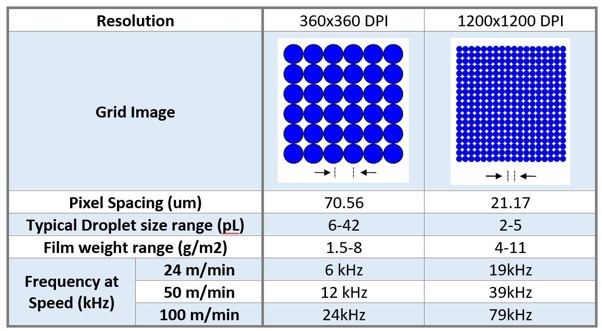

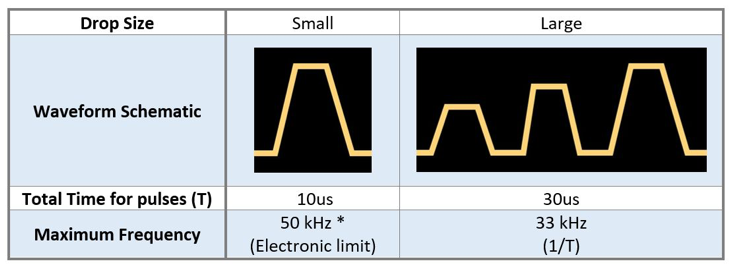

Be careful though. To improve the print quality by balancing individual dot visibility with the ability to get coverage, print head makers introduced greyscale heads. These printheads can produce drops of multiple volumes depending on the waveform applied to them. This is superb invention, but it is important to remember that the different drop sizes need different amounts of time to fire as shown very simply below.

Why does this matter? The maximum print frequency on a printhead specification is often specified for 1-pulse (binary), whilst the maximum volume is for multi-pulse (greyscale). The maximum frequency for the largest drop size is usually lower; making big drops at high frequency is not going to happen.

With this in mind, once you have determined the speed and frequency you need to print at, you should be able to narrow down the printheads to choose from even more.

WHAT TO DO IF THE PRINTHEAD YOU NEED DOESN’T EXIST

Let’s say that you determine that you need 1200dpi resolution and want to print at 10 m/s, so you calculate that you need to print at a frequency of 472 kHz. You scour the marketplace and discover that uh-oh, there is no printhead that can do the job. There are still techniques that you can use to accomplish what you need without having to invent your own printhead.

The first trick is that you are not limited to only using a single printhead. By putting two printheads in the print process, one after another, you are able to double your throughput. In this case, you could either have each printhead print at 600 dpi and 472 kHz, or you could have each printhead print at 1200 dpi and 236 kHz. By stacking multiple rows of printheads together, you can reduce the individual required throughput of each head to get to achievable levels.

Another technique to use to your advantage is the concept of “apparent resolution”. The basic idea is that a grayscale inkjet print (using different drop sizes) is visually equivalent to a higher resolution print made up of uniform drops. You can lower your resolution requirement without sacrificing anything to the viewer. If you are interested more in this technique, look it up.

Learning Something New? Subscribe to Receive Future Articles

THE TYPE OF INK YOU ARE WORKING WITH

The final thing to check is that the head will survive exposure to the ink type you have in mind. Printhead manufacturers always advise the ink platform suitability on their data sheets (like UV, solvent or aqueous). Be careful of making assumptions, however. Not all inks of each type are the same!

If you are a printer or converter who has been given a new ink, then ask the ink manufacturer what they have done to test suitability. Usually “approved” or “certified” inks have gone through a process of accelerated testing as a minimum.

If you are the ink provider, obtaining the material compatibility kits (MCK) for a given head is a sensible approach; just in case you are asked for the data! Alternatively, you might be able to pay the manufacturer to do it for you. Just remember, if the ink attacks the head materials it’s not normally reversible so don’t forget to put it on your checklist.

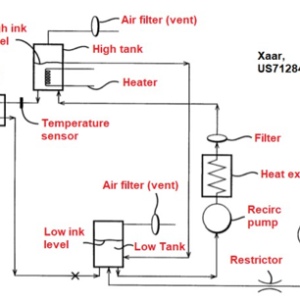

FREEDOM TO DEVELOP

It is worth noting that printhead manufacturers are not all the same when it comes to what you are allowed to do while working with their printheads. The amount of openness to develop on a printhead varies highly from one manufacturer to the next. For example, some manufacturers allow you to modify the waveforms that are being applied to the printhead, so you can optimize a waveform to better suit your ink. Some manufacturers do not, and you have to develop your ink to the waveform. Some manufacturers have open printhead architecture, which allows you to use the printhead in places other than the manufacturer’s printer, such as in a lab. If you want to be able to use a printhead on a JetXpert dropwatcher or JetXpert Print Station, then you are limited to printheads that allow you to do so. This freedom to develop outside of the manufacturer’s printer and default settings is not useful for every style of inkjet development, but it may be extremely helpful for some and is worth considering.

CONCLUSION

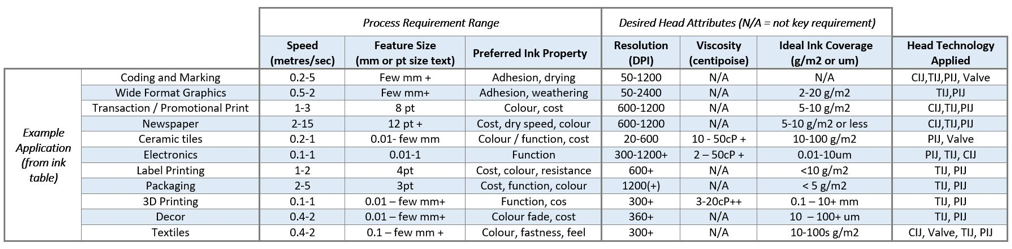

At this point, you should hopefully be considering the resolution and speed that you want to print at in order to make your printhead selections. This will guide your decision towards selecting which category of jetting technology meets those specs, whether it is drop on demand (DOD), continuous inkjet (CIJ), or another printhead design. From there, you can dig deeper into what the capabilities of each individual manufacturer and printhead model are to find the ones that match your needs and ink. Although there are no hard-fast rules, it helps perhaps to look at the varying requirements of some existing application spaces. In the table below, we conclude with a non-exhaustive summary of the potential considerations that will influence how the application determines the head.