The Top 4 Solutions for Latency / De-Cap

Latency, open time, and de-cap are some of the terms used to describe the negative behavior of ink after periods of sitting idle in the printhead. You may notice that after taking the night off, the first print of the day is no good; this is latency at work! Depending on your setup and how quickly your fluid can evaporate, latency can have adverse effects after days, hours, or even minutes of ink at rest. Minimizing the impact of latency has the potential to save you huge maintenance headaches and quantities of material over time, so it is a worthwhile project to add to your inkjet development. In this article we look at some of underlying causes of nozzle failure due to drying and what can typically be done about it, both through ink chemistry and printer design.

WHAT DOES LATENCY LOOK LIKE?

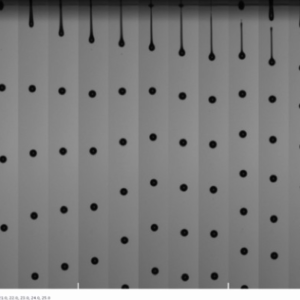

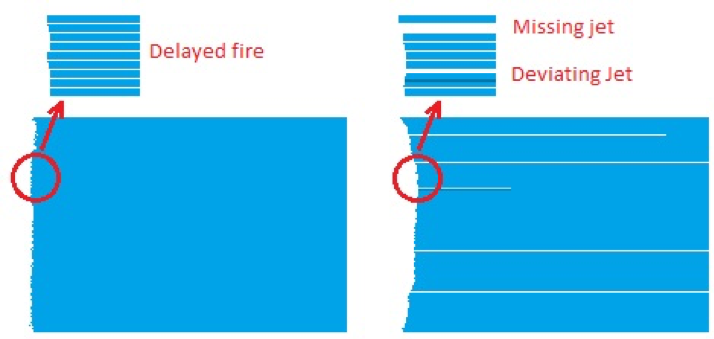

If your ink or jettable fluid demonstrates latency effects, there is a problem to overcome with nozzle failure that is time-dependent. This behavior is usually caused by local change in the ink concentration near the nozzle opening, normally due to evaporation of the ink carrier. Once printing is resumed, this may result in drops that are firing abnormally or not firing at all. You may see delayed firing, where there is a ragged leading edge of the print since every nozzle does not actually begin jetting at the same time. Deviating jets, where the drops do not fall where you expect, could be caused when the first drops have low volume, slow velocity, or poor trajectory. Missing jets are found when the nozzle has dried so much that no amount of jetting is able to recover it. It is common that you may see all three, depending on the time the ink has sat in the head. In the diagram below, you can see what each of these may appear as in the print.

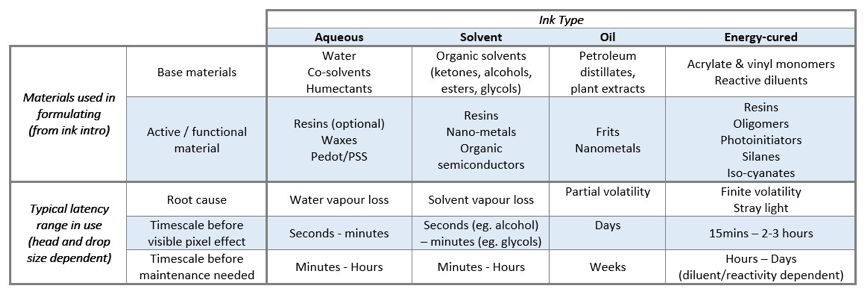

How long it takes for an issue to occur is very ink and printhead-dependent, but we try to establish reasonable expectations below to compare the different ink types.

MANAGING LATENCY WITH FORMULATION

When it comes to ink formulation, the trick is to find the right balance so that the nozzles do not dry but the print does. More realistically, you want the nozzles to dry at a reasonable interval and the print to dry at a reasonable speed, so that it can be rolled or stacked without needing too many heaters. Inks with volatile carrier solvents, such as alcohols or water, are more prone to drying and have greater challenges with latency. The common principle is to select additives (humectants) with higher boiling points to slow the rate of evaporation. In aqueous and solvent inks, glycols and glycol ethers are most commonly used for this purpose, like glycerol/diethylene glycol or DEGMEE, respectively.

Latency can also be influenced by pigment dispersions and especially heavy inorganic pigments, like those used in ceramics. Finding the right balance of particle size and distribution is important because the stability of the pigment dispersion is tested as the printhead idle time increases. For example, if the particle size is too big, it is more prone to settling and eventually clogging.

When using a dropwatcher to study the impact of different ink formulations on latency, you may find that you spend a lot of time waiting as the printhead sits idle. If you have a target idle time in mind, such as 30 minutes, someone needs to be there to start jetting and capture data at that time. But what if you want to find the maximum idle time for an ink? JetXpert has an add-on called Latency Sweep that can help. The system will automatically start and stop jetting, capturing images and data along with way, then report to you that maximum idle time before drop formation was negatively impacted.

Learning Something New? Subscribe to Receive Future Articles

MANAGING LATENCY WITH MACHINE DESIGN

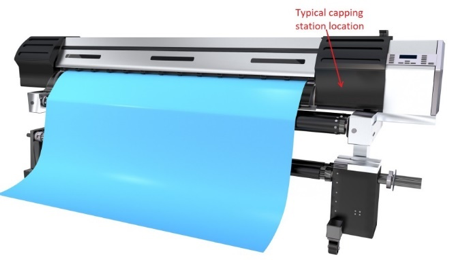

Addressing latency challenges through machine design means minimizing printhead contact with air, thus reducing the rate of the fluid drying. This can be achieved by capping stations, where a material is pressed against the nozzle plate when the printhead is idle, sealing off the air.

In multiple-pass printers, the effects of ink drying are relatively easily avoided with capping. Due to the geometry, the heads can be “parked” into the maintenance position immediately after printing stops, just like the typical home/office inkjet printer. Longer periods of nozzle non-use, when printing a large area of a specific colour, can be avoided using “prime bars” down the side of the media. These are patterns that systematically fire all the nozzles to keep them refreshed, which can then be cut off afterwards.

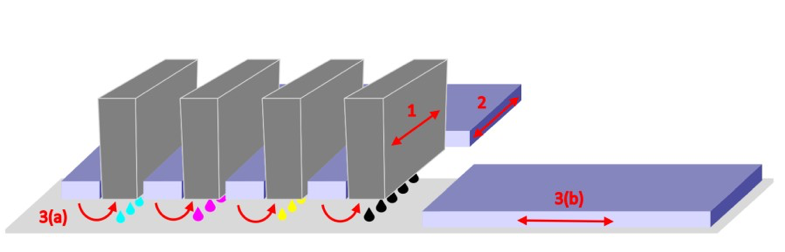

In single-pass printers, capping the printheads gets more complicated with so many printheads to keep safe. From a design perspective, there are several capping options: (1) to have a machine that is at least twice as wide as the print width and thus move over to cap, (2) move the cap from the side to under the heads (thus lifting the heads up to make space) or, commonly in ceramics, (3) have a cap storage location upstream or downstream of the print direction as (a) one piece or (b) several.

An additional challenge for single-pass printers is that there is a lot less time before the printed surface makes physical contact in some way, so drying speed is a bigger concern. This makes latency more common as drying time in the nozzles is also sacrificed. Fortunately, there are other options for addressing latency in these challenging systems.

MANAGING LATENCY WITH PRINTHEAD

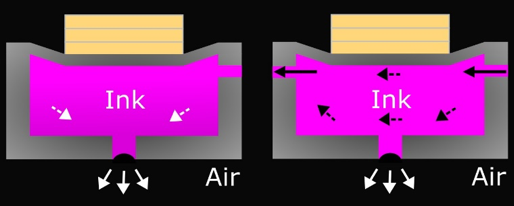

As well as choosing your ink, hopefully you’ve thought about choosing your printhead quite carefully too. We have introduced printhead recirculation elsewhere and the potentially critical role it can play in improving latency as well as reliability. By constantly refreshing the nozzles, recirculation helps ensure the ink is well mixed, even as the carrier fluid is drying. In the schematic below, we portray how recirculation can help keep the ink from changing from its manufactured state to something less controlled in viscosity.

In the first image the evaporation from the nozzle results in localized concentration variations that drive diffusion effects (white arrows) that are can be different for materials with varying solubility in the ink base. By keeping the ink flowing through the channel, the ink available to jet is more pristine, although very local interfacial effects are still possible.

MANAGING LATENCY WITH WAVEFORM

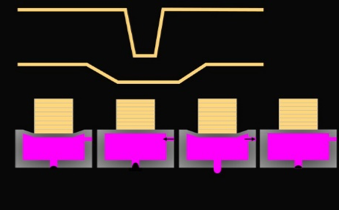

If the recirculation concept introduces more design complexity than desired in your application, spitting and tickling are two additional printhead-related methods used. Both approaches do need the capability to be made available within the printhead controller, so they are not supported by all systems. Nevertheless, they are now common enough to justify talking about them more. Spitting and tickling work by keeping the ink moving in the region of the nozzle, but at a lower frequency than printing. The key difference between them is whether a drop is created or not. This distinction has some obvious implications and some less apparent ones.

Spitting works by occasionally firing drops out of all the nozzles to refresh them. The challenge when spitting is having to catch the droplets, otherwise it will impact the printed image, so the method is usually only used when in the cap position. Some people think it is waste of ink, but the process can be quite efficient at lower frequency, especially compared to a purge to rectify nozzle failures. In order to minimize how much ink is wasted, it is important to know the minimum amount of spitting required to refresh the nozzles. JetXpert makes a tool called Latency Multidrop, which can automatically determine the recovery time for you, ensuring that you don’t use more ink than necessary.

Tickling is a similar concept, but when all the nozzles fire, the drive voltage or pulse timing of the waveform is reduced to ensure a drop is not ejected. This allows the ink near the nozzle to be moved around but never actually leave the head. There are two limitations; both present themselves if the stoppage is longer term. First, because the fluid is still evaporating, this technique is mixing a fluid around the chamber that is getting thicker and thicker over time. Eventually, the fluid will be too thick and the effectiveness is lost. Secondly, the self-heating of the head can cause drop variations when jetting eventually is resumed which can make latency even worse. Both these issues are overcome by introducing the recirculation in combination. Studies have shown this to be very effective.